|

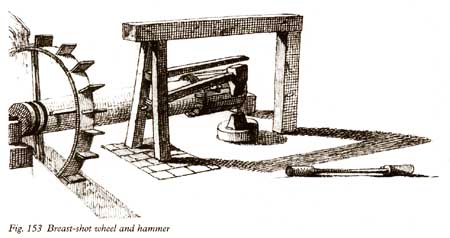

Iron forge

at Caerleon

On 25 June I continued my trip in the afternoon in the company

of two Quakers, Mr Roberts and Mr Williams, to Caerleon, which

means a town for a Roman legion. It is located eight miles from

the Severn on a navigable river. Mr

Roberts has recently built a forge with three hearths, a little

way from the town. We went to see it, and it is shown in drawing

no. 153.

The

frame of the hammer was built of brick. The breast-shot wheels

for the bellows and hammer and their buckets were designed according

to Spanish or Biscayan practice. Nevertheless, the head of water

here is high enough to permit the use of over-shot wheels, but

they would not be more advantageous in this case when the wheels

run at high speed, because it is more difficult for the water

to escape from the deep buckets that one must employ on over-shot

wheels, than to leave the shallow and open buckets on a breast-shot

wheel.

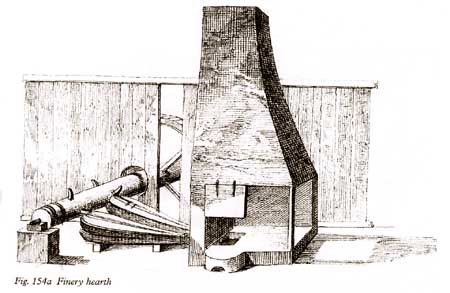

The

three hearths were divided in such a way that two were used for

the melting of the iron and called finery hearths, while the third,

on the other hand, was only used for forging the bars and called

a chafery hearth.

The

finery hearths are made of cast-iron slabs, 2 feet long, 15 inches

wide and 6 inches to 6½ inches deep below the tuyere, which

was forged of wrought-iron.

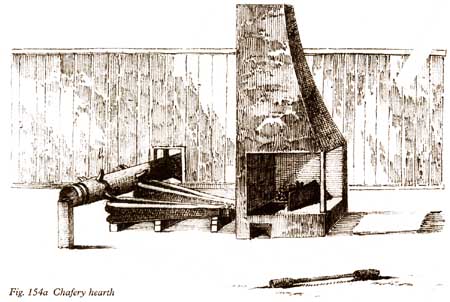

The

chafery is larger across, so that it is possible to place in it,

side by side, four lumps of iron as they come from the finery

hearths, drawn out in the middle to a length of 1 foot, 6 inches

or 2 feet as shown in the attached drawing no. 154a [sic.] [see

footnote b]. Across the end of the chafery hearth there is an

upright slab of iron, which serves to keep the coal together and

heaped up high [Fig. 154b] [sic.].

This

gives a more intense heat. Both kinds of hearths use nothing but

charcoal, which mostly is made in this locality from oak, lime,

beech, etc. Sometimes birch and other deciduous trees are mixed

in. Charcoal is very expensive here, because in the neighbourhood,

for several miles around, there are no other trees than those

planted in the hedges surrounding the fields and meadows.

Calculation

of the price of the iron

|

|

|

One load

of coal here costs 36 shillings. A load consists of 12 horse loads

and each horse load is a sack, which should fill a coal-measure

3 feet square and 20 inches deep [see footnote d].

In the refinery

the workers are allowed 18 horse loads, or one-and-a-half loads

of coal per ton of iron. At the chafery, 12 sacks or one load

of coal is allowed per ton of iron. The total consumption of coal

is thus two-and-a-half loads, or £5.8s.0d. [see footnote

e]. Three men work at each refinery hearth, or six altogether,

paid 10s 6d per ton. Two refinery hearths can produce 6 tons of

iron per week and the same 6 tons can be forged to bars in the

chafery, if only there is sufficient water. At this forge water

is sometimes scarce, particularly when the weather is very dry.

The pig iron used at this forge is made at Abercarn, which lies

further away from the sea, 18 English or three Swedish miles from

Caerleon. It is brought here on horseback and the transport costs

8 shillings per ton. The pig iron is in the form of slabs 2 feet,

3 inches to 2 feet, 6 inches long and 6 inches wide at the middle.

They are nowadays reckoned to cost £6 per ton at the furnace.

26½cwt of pig iron or one-and-three-quarters tons [see

footnote f] is allowed per ton of bar-iron, but the finers told

me that they do not need quite so much when the pig iron is of

good quality. For each bloom or loop, three-quarters of a hundredweight

or 84 lb of pig iron is used and 20 loops are made per 24 hours.

Footnotes

Please

note, the footnotes have been renumbered for convenience.

[b] The 'lumps of iron' shown are clearly in the form of what

are known as 'anconies', the products of forging a bloom in the

finery. The ends are usually of rough square section, finished

to the final shape of the bar in the chafery.

[c] This calculation must be regarded as approximate as RRA allows

one-third wastage, and in fact 3 x £14.13s.4d = £44,

so an extra 13s.4d has crept in.

[d] Presumably 'load' means a wagon load. A measure of the dimensions

given would have a volume of 15 cubic feet or 11.7 bushels.

[e] Again, an error has crept in: 2.5 x 36s = £4.10s.

[f] In fact, one-and-a-third tons.

|

|